The packaging machine is a kind of machine that packs the products to protect and beautiful. A wide variety of such as: Forming Filling Sealing Packing Machine, and the like. So how do they need to be maintained?

The packaging machine must be operated by a fixed person, and must be trained by the brand manufacturer, able to master the booting, bag making procedures, simple instrument debugging, changing parameters, etc.;

Form Fill Sealing Machine For Olive Oil Packing

Mechanical instrument debugging personnel must undergo strict training from Jun brand manufacturers, and be proficient in instrument performance, work procedures, operation modes, working conditions, common troubleshooting and handling;Automatic Syrup Liquid Packing Machine

It is strictly forbidden to operate computer instruments without training personnel. Daily maintenance must ensure that the computer instrument box is clean and dry inside and outside; the terminal block is not checked for looseness or shedding. Ensure that the circuit and airway are unblocked.

Basic cleaning includes:

1. After the shutdown, the metering part should be cleaned in time. For example, the packaged sugar, sapphire root, salt, etc., must ensure that the cleaning tray and turntable are cleaned every time.

2. For the heat seal body, it should be cleaned frequently to ensure the clear texture of the seal.

3. Photoelectric tracking light head, that is, electric eye, should also be cleaned regularly to ensure small error of cursor tracking.

4. The materials scattered on the tray should be cleaned in time to keep the parts clean.

5. Regularly clean the dust inside the electric control box to prevent malfunctions such as poor contact.Capsule Pill Blister Packing Machine,

The new packaging machine must check and fasten the transmission and moving parts within one week of use, and refueling and maintenance; regular maintenance must be checked every month;

Vinegar Olive Oil Packing Machine

Basic maintenance:

1. Regularly check the screws of each part of the packaging machine to avoid looseness.

2. Pay attention to the waterproof, moisture-proof, anti-corrosion and anti-rat parts of the electrical parts. The electrical control box and terminal block should be kept clean to prevent electrical failure.

3. When the machine is stopped, the two heat sealing rollers should be in the open position to prevent the packaging material from being burnt.

4. Timing the gear meshing part of the packaging machine, the bearing oil filling hole and the moving parts are lubricated with oil. When filling the lubricating oil, please be careful not to drop the oil on the transmission belt to prevent the slipping or the belt from aging damage.

Folding daily maintenance

Several key points for the maintenance of packaging machinery: cleaning, fastening, adjustment, lubrication, anti-corrosion. In the ordinary production process, each machine maintainer should do it. According to the maintenance manual and maintenance procedures of the machine packaging equipment, strictly carry out various maintenance work according to the specified period, reduce the wear speed of the parts, eliminate the hidden troubles of the fault, and prolong The life of the machine.

Maintenance is divided into: routine maintenance, regular maintenance (minute: primary maintenance, secondary maintenance, tertiary maintenance), special maintenance (point: for seasonal maintenance, disable maintenance).

Folding routine maintenance

With cleaning, lubrication, inspection and fastening as the center, routine maintenance should be carried out as required during and after the work of the machine.

The first-level maintenance work is carried out on the basis of routine maintenance. The key work is to lubricate, tighten and inspect all relevant parts and their cleaning work.

The secondary maintenance work focuses on inspection and adjustment. Specifically check the engine, clutch, transmission, transmission components, steering and brake components.

The third-level maintenance focus is to detect, adjust, troubleshoot and balance the wear of each component. Diagnose and condition check the parts that affect the performance of the equipment and the parts with fault signs, and then complete the necessary replacement, adjustment and troubleshooting.

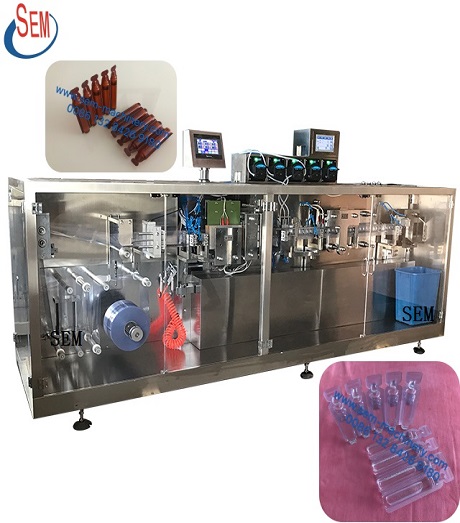

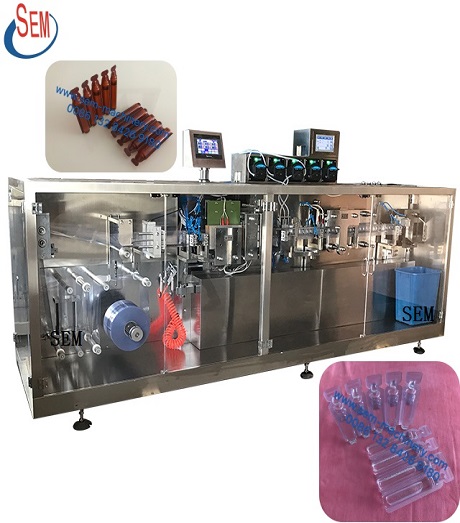

Plastic Vial Form Fill Seal Machine

Folding season maintenance

It means that the packaging equipment should focus on the detection and repair of components such as the combustion system, hydraulic system, cooling system and starting system before entering the summer and winter.

Folding stop maintenance

It means that the packaging equipment should be cleaned, plasticized, matched, and preserved when it needs to be deactivated for a period of time due to seasonal factors (such as winter vacation).

Sealing and cutting method: bottom blade

Maximum outer diameter of the film roll: DIA 250mm x W 470mm

Folding fault resolution

The electromagnet does not pick up. The solution is: first check whether there is a problem inside or outside the host; secondly, check the solenoid fuse to see if the electromagnet has signs of encourage, eliminate mechanical jam, and detect when everything is normal. Internal power supply; commonly encountered in weighing packaging machines is the cause of such failures: sensor damage, bridge voltage failure, line connection or interruption is wrong, the elimination method is: detection sensor and wiring or host Load signal, close to detect the bridge and amplifier circuit or computer output display circuit, or remove the host, apply a clear signal through the internal short circuit to determine whether the fault is in the machine or from the switch, and then solve the problem.